Food safety monitoring plays a vital role in any business operating within the food industry. From grocery stores and convenience stores to fast food chains, restaurants and catering companies, each type of operation must instill a sense of confidence in consumers that the food and beverages they purchase will be safe from contaminants, including disease-causing bacteria.

One way to help maintain the quality of food and its safety, as well as its shelf life, is through the use of various monitoring systems. Refrigerated and frozen foods must be maintained at specific temperature levels at all times. If there are variances in the temperatures, they must not exceed certain levels, or else the food could become contaminated.

What Is the Food Industry’s View on Monitoring?

The food industry is a trillion-dollar industry when you factor in all operations, from food production and manufacturing to the end products purchased by consumers at their favorite restaurants and grocery stores. Anytime an outbreak occurs, it hurts consumers and consumers’ confidence in the brands that experienced the outbreak. In addition, those brands could face potential lawsuits, further tarnishing their images.

As such, everyone at every level of the industry is concerned about food safety and utilizes various monitoring methods to limit and reduce the risks of contamination and food-borne illness outbreaks. While each operation can take a different view and utilize different monitoring methods, they are in agreement about setting appropriate safety and quality standards to maintain consistency.

How Does Monitoring Help Ensure Safety and Quality?

Monitoring helps ensure quality and safety and shelf life by requiring that food, as finished goods or as in process or raw material, will be handled in specific ways. Implementing monitoring processes should include those that can be tracked to identify potential issues and concerns over the safety and quality of food products.

For example, coolers and freezers need ongoing temperature monitoring solutions in the restaurant industry. These solutions must alert employees and others when a freezer or cooler temperature falls outside the safe operating zone.

Furthermore, food within freezers and coolers should be stored to prevent cross-contamination between food products. For instance, raw chicken should be stored separately from other meats, and any containers should be washed and sanitized before being reused. Cooked foods should also be stored in a different area from raw foods.

By implementing the right monitoring solutions, those in the food industry can gain several benefits, including:

- Makes collecting data easier.

- Stores data track.

- Offers the ability to convert data into customized reports.

- Helps businesses comply with specific federal, state and local regulations, rules, and laws.

- Makes it easier to track the source of potential outbreaks before they occur.

- Reduces the potential for human error.

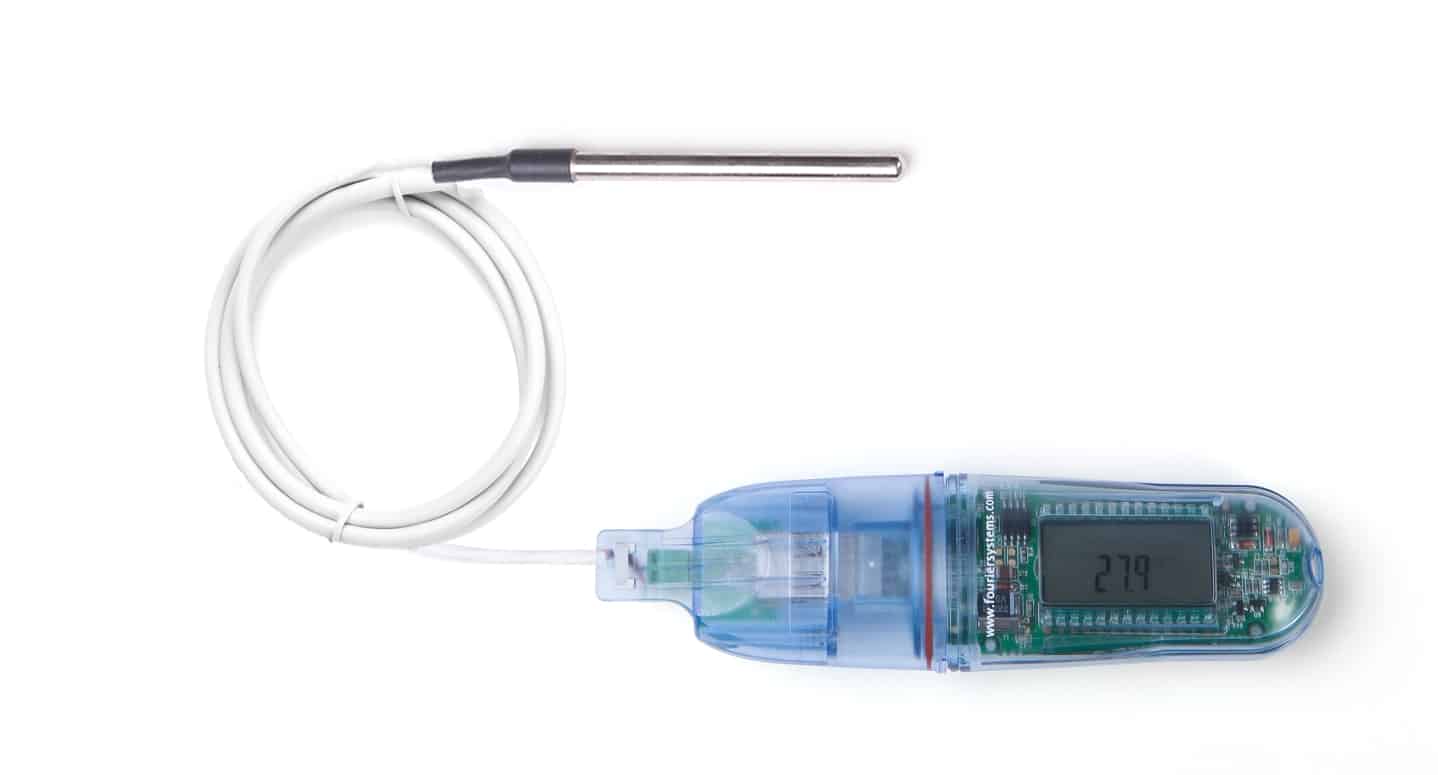

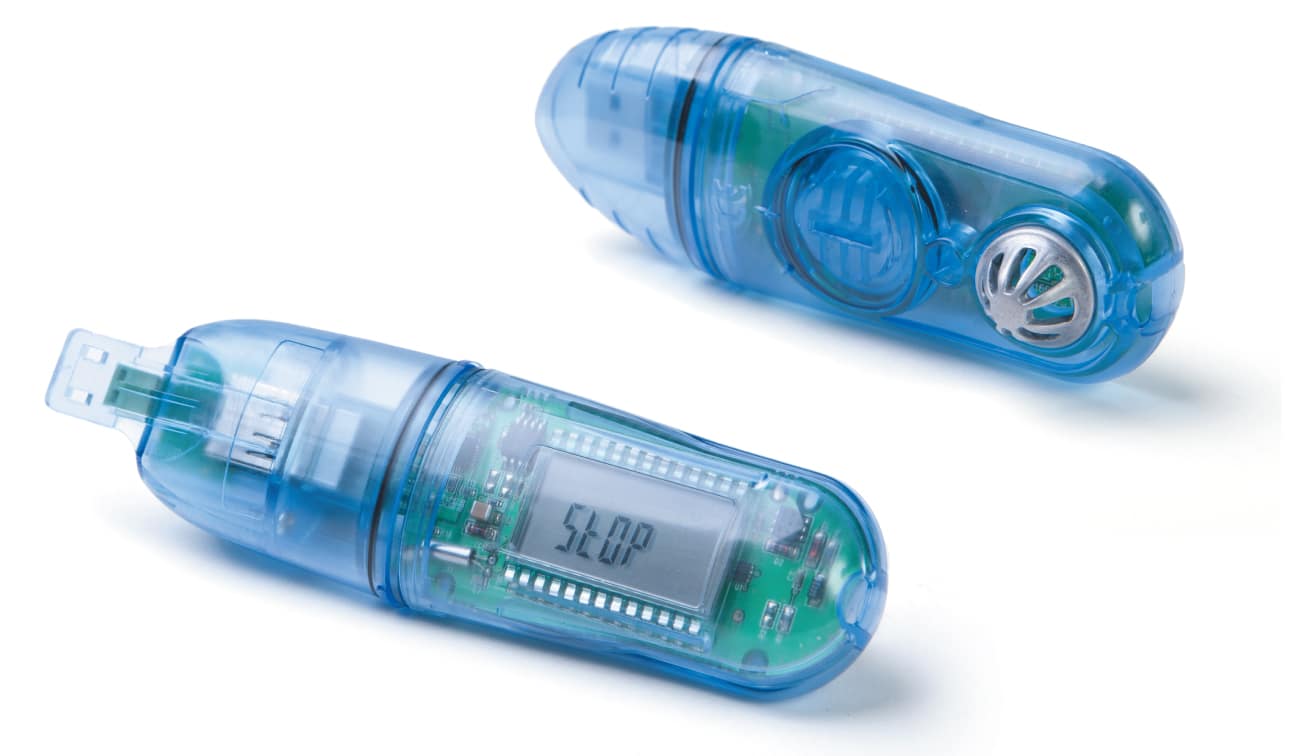

Fourtec offers HACCP-compliant (Hazard analysis and critical control points) data loggers for keeping your food safe throughout the food cycle. Our solutions suit various food-related applications including food laboratories, production floors, supermarkets, pasteurization, refrigeration, storage and shipping, supermarkets restaurants and catering companies, Hotel’s Food and Beverages team and much more, while complying with FDA and CFR Part 11 regulations.