MicroAir-The New Wifi Temperature and Humidity Logger

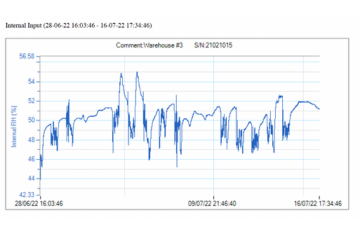

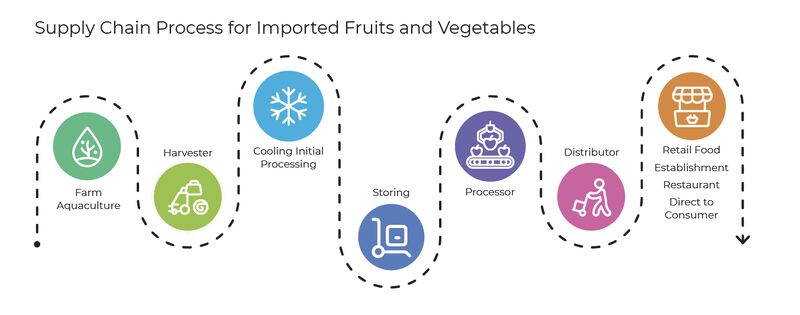

The MicroAir WiFi Logger is Fourtec’s NEW Wifi Temperature and Humidity logger that enables real-time monitoring for various industrial and supply chain applications, storage, cold rooms, computers and communication rooms.The MicroAir WiFi Measurement Temperature range is -40°C to 80 °C (-40°F to 176°F), and the Humidity range is between 5% to 95%. The MicroAir WiFi…