Wireless Overview: Real Time Multi-Logger Monitoring

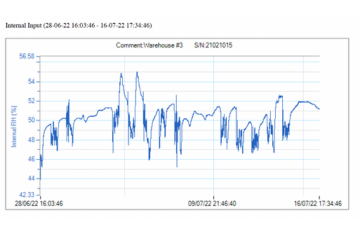

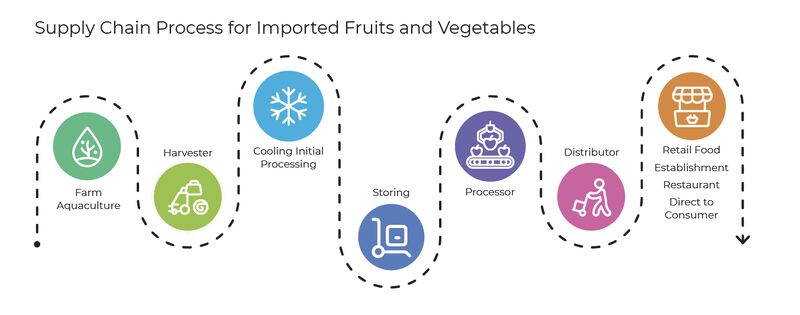

A trucking company uses Fourtec’s BluLite loggers with the new Wireless Overview in FourtecLite to monitor multiple devices in real time, generate automated reports, and maintain cold chain compliance.